- FUSION 360 CAM HOW TO

- FUSION 360 CAM MANUAL

- FUSION 360 CAM FULL

- FUSION 360 CAM SOFTWARE

- FUSION 360 CAM WINDOWS

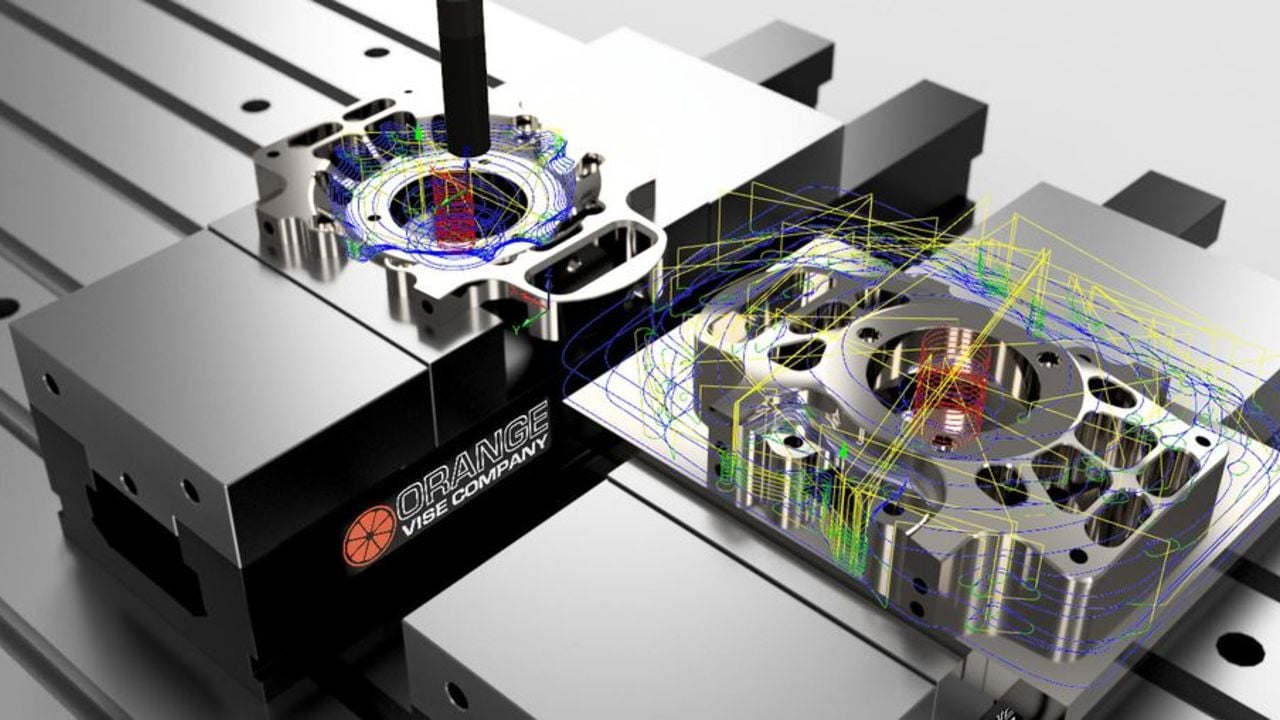

G-code is easy to read once you understand the format. This is the set of instructions that controls a machine’s actions, including speed, feed rate, coolants, etc. To do this, we convert all of our machining information to a language called G-code. However, we can’t just give a machine a bunch of instructions in English. Once the model is prepared for machining, all information gets sent to a machine to produce the part physically. Image courtesy of Kansas City Kit Company Running a Contour toolpath in Fusion 360. Configuring nesting where the CAM system will decide the best orientation for a part to maximize machining efficiency.Setting any required machine parameters, including cutting speed, voltage, cut/pierce height, etc.Creating a toolpath for the model, a set of coordinates the machine will follow during the machining process.Checking if the model has any geometry errors that will impact the manufacturing process.

FUSION 360 CAM SOFTWARE

Machining is the controlled process of transforming raw material into a defined shape through actions like cutting, drilling, or boring.Ĭomputer Aided Manfacturing software prepares a model for machining by working through several actions, including: Once your CAD model is imported into CAM, the software starts preparing the model for machining. If you’re using a tool like Fusion 360, both CAD and CAM exist in the same world, so there’s no import/export required. This is traditionally done by exporting a CAD file and then importing it into CAM software. When a design is complete in CAD, it can then be loaded into CAM. In CAD, any design is called a model and contains a set of physical properties that will be used by a CAM system. Engineers will make either a 2D or 3D drawing, whether that’s a crankshaft for an automobile, the inner skeleton of a kitchen faucet, or the hidden electronics in a circuit board. The start of every engineering process begins in the world of CAD. You can design the most elegant part in your CAD tool, but if you can’t efficiently make it with a CAM system, then you’re better off kicking rocks. CAD focuses on the design of a product or part.

Today, there’s no design too tough for any capable machinist shop to handle. As an industry, we’ve spent years building and refining the best manufacturing machinery around. These three components are glued together with tons of human labor and skill.

FUSION 360 CAM HOW TO

Software that tells a machine how to make a product by generating toolpaths.What is CAM? Computer Aided Manufacturing (CAM) is the use of software and computer-controlled machinery to automate a manufacturing process.īased on that definition, you need three components for a CAM system to function: What happens behind the scenes? Keep reading, and you’ll find out. When you need something made, not just designed, CAM is your answer. We’re the ones that give the power of flight to airplanes or the rumble of horsepower to automobiles.

FUSION 360 CAM FULL

In a world full of physical stuff – whether that’s products, parts, or places – Computer Aided Manufacturing (CAM) makes it all possible. I guess that was the whole point.Italiano (Italian ) Computer Aided Manufacturing (CAM): The Complete Introduction for the Beginner’s Mind I'm not that commited nor have funds to justify the full license. 5mm drill (so sloooowly) and the time it took to move from hole to hole was NOT insignificant. All in all I thought the no rapids wouldn't be a big deal but yesterday I was drilling lots of holes with. I guess analysing cgode based on the height above stock might be possible but IMHO won't work reliably enough. Again I get why they did it, but I don't see a quick workaround. What I saw people commenting on autodesk forums fusion no longer gives information to post-processor what is a cutting move and what is a non-cutting move. My question did anyone already did something similar so I wont be reinventing the wheel?

FUSION 360 CAM WINDOWS

Simple enough to do in powershell and add to windows right-click menu.

FUSION 360 CAM MANUAL

I use manual tool change so I can export multiple files for every tool-job and then combine them with simple "M6" in between. Now without the possiblity to export jobs with multiple tools to single cgode file and no rapids I'm looking for workarounds.

I get why autodesk did what they did but it's a huge pain in the back for me.

Really liked the CAD-CAM-postprocessor-CNCjs workflow I used. I'm a relatively new-to-the cnc game hobbyist.

0 kommentar(er)

0 kommentar(er)